Why Automated Inventory Control Matters for Your Marine Business

Automated inventory control is the use of technology—like barcode scanners, RFID tags, and specialized software—to track and manage stock levels in real time with minimal manual input. Instead of relying on spreadsheets, clipboards, and guesswork, automated systems provide instant visibility into what you have, where it is, and when to reorder.

Quick Answer: What is Automated Inventory Control?

- Real-time tracking: Know your stock levels instantly across all locations

- Automatic reordering: Set thresholds that trigger purchase orders automatically

- Reduced human error: Eliminate manual data entry mistakes

- Cost savings: Prevent overstocking and stockouts that drain profits

- Better decisions: Use accurate data for forecasting and planning

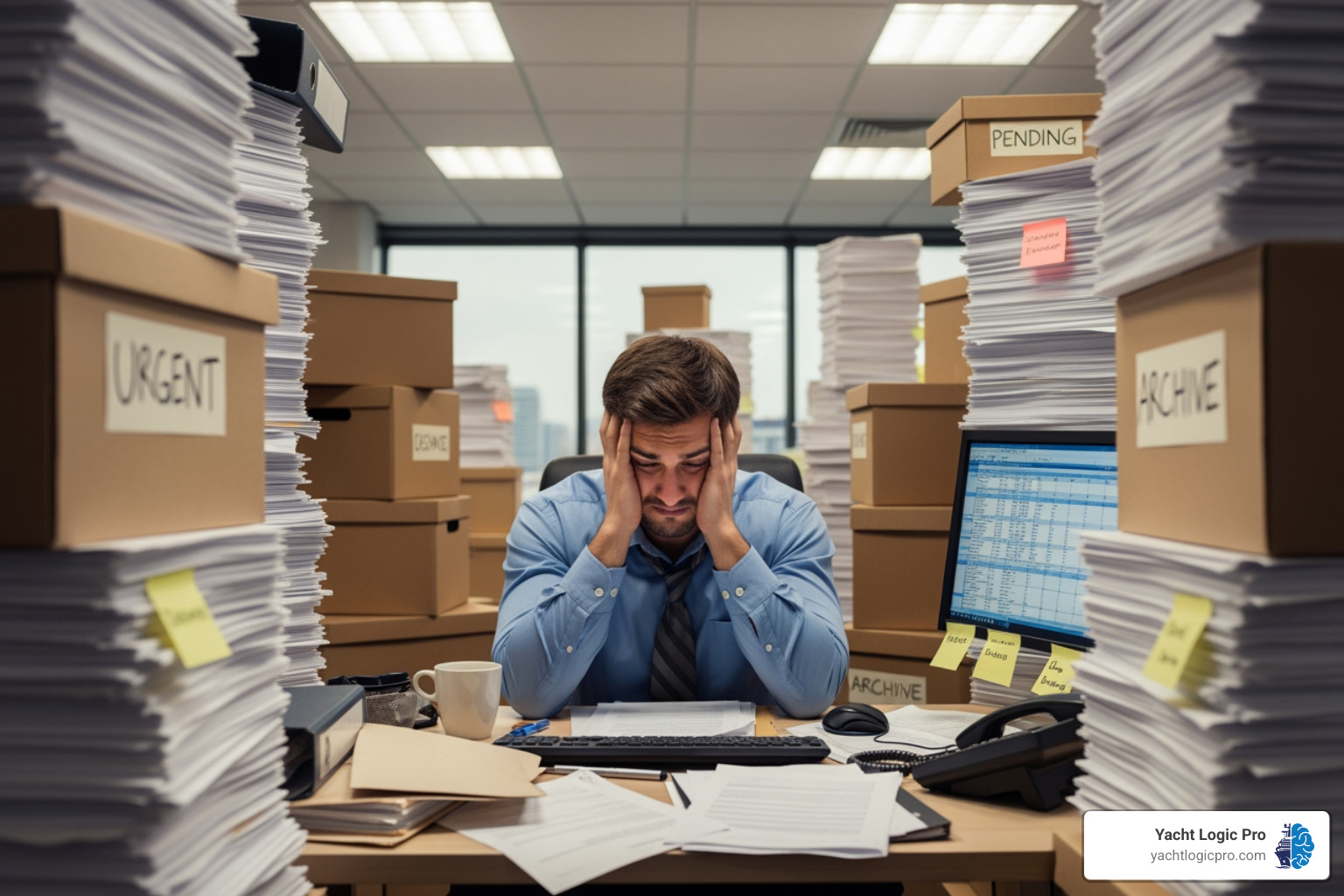

If you run a marina, boatyard, or yacht service business, you know the pain. You’re juggling parts for multiple jobs, tracking consumables across warehouses, and trying to remember if you have that critical component in stock. Meanwhile, a technician is standing idle, a customer is waiting, and revenue is slipping away.

The numbers tell the story. Research shows that 43% of retailers rank inventory management as their top operational concern. For marine businesses, the stakes are even higher—specialized parts, long lead times, and seasonal demand create a perfect storm of complexity.

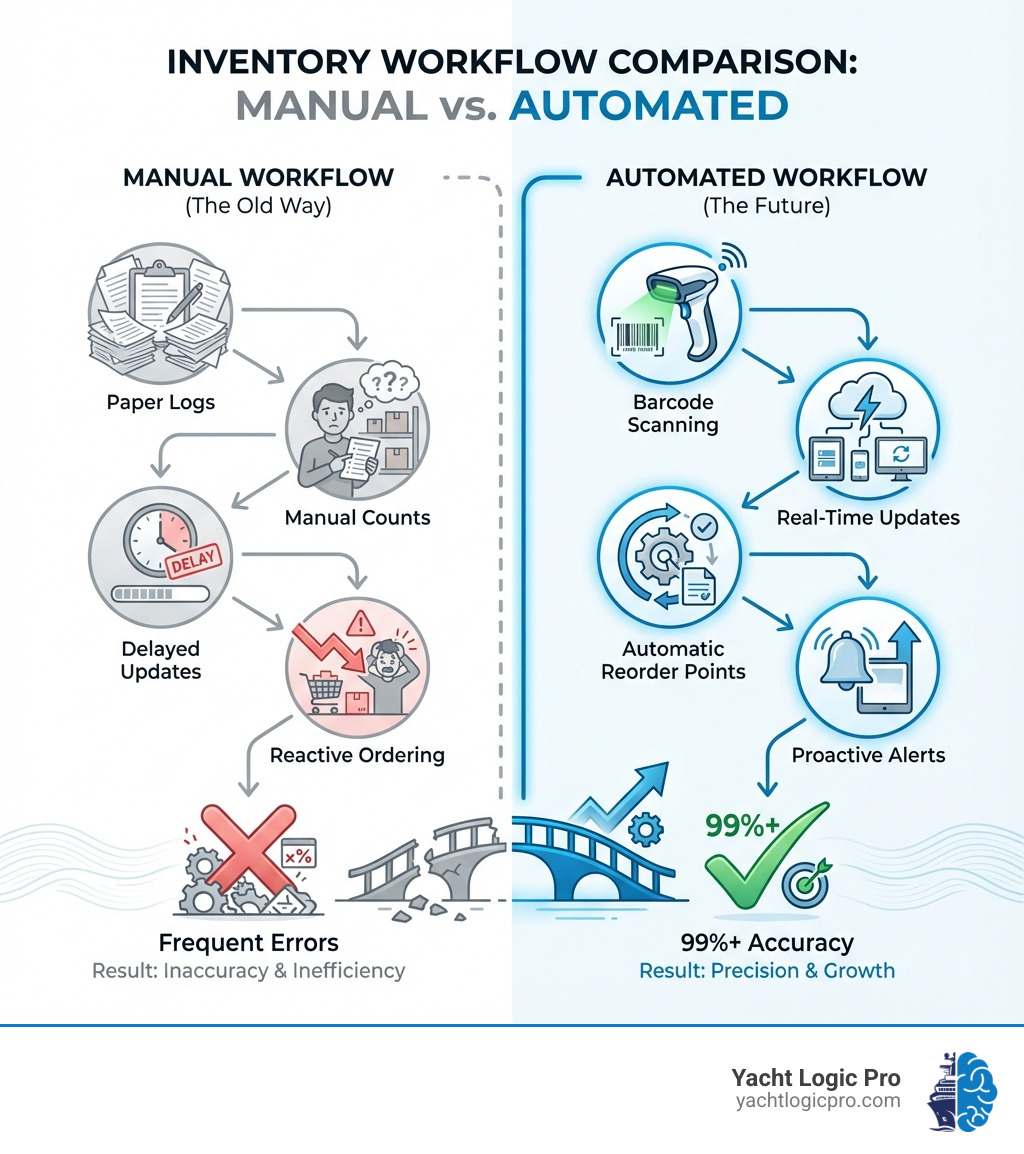

Manual tracking with spreadsheets and paper logs leads to predictable problems: inaccurate stock counts, surprise shortages, excess inventory tying up capital, and wasted labor hours searching for parts. One study found that overstocks and stockouts cost North American retailers $349 billion in lost sales in a single year.

The solution isn’t working harder—it’s working smarter. Automated inventory control transforms your operations from reactive firefighting to proactive management. Instead of finding you’re out of stock when a customer needs it, you get alerts before it happens. Instead of guessing what to order, the system tells you based on real usage patterns.

For marine service businesses dealing with thousands of SKUs, multiple locations, and complex jobs, automation isn’t a luxury anymore. It’s the key to staying competitive and profitable.

The High Cost of Manual Inventory vs. The Power of Automation

We’ve all been there, staring at a spreadsheet that just doesn’t add up, or searching frantically for a part we “swear we just saw.” This struggle is the reality for many businesses still relying on manual inventory management. In fact, nearly half of small businesses admit they don’t have an inventory management process at all. For those that do, 43% of retailers ranked inventory management as their top concern. It’s a recipe for headaches and, more importantly, lost profits.

The challenges of manual inventory are numerous and costly:

- Inaccurate stock levels: Manual data entry is prone to human error, leading to discrepancies between what you think you have and what’s actually on the shelf. This can result in ordering too much or not enough.

- Wasted time: Hours spent on physical counts, cross-referencing spreadsheets, and searching for misplaced items divert valuable employee time from more productive tasks.

- Increased carrying costs: Overstocking ties up capital, requires more storage space, and increases the risk of items perishing or becoming obsolete. Globally, 8% of inventory perishes or is discarded annually at a cost of $163 billion.

- Lost sales and frustrated customers: Stockouts mean you can’t fulfill orders, leading to lost revenue and unhappy customers who might take their business elsewhere. Overstocks and stockout experiences cost US and Canadian retailers $349 billion in lost sales in 2022.

- Operational inefficiencies: The ripple effect of poor inventory management can slow down your entire operation, from procurement to order fulfillment.

These hidden costs can silently erode your business’s profitability, much like the unseen wear and tear on a vessel. You can learn more about these financial drains in our article on The Hidden Costs of Manual Yacht Maintenance Tracking.

In contrast, automated inventory control offers real-time tracking and proactive management. It shifts your business from constantly reacting to problems to intelligently anticipating needs. This means you gain a clear, up-to-the-minute picture of your inventory, enabling smarter decisions and smoother operations.

What is Automated Inventory Management?

At its heart, automated inventory management is about leveraging technology to streamline and optimize the process of tracking, controlling, and organizing your stock. It uses software and various hardware components to monitor stock levels, sales, and supply chain activities with minimal human intervention.

Think of it as having an ever-vigilant assistant who knows exactly where every item is, how much you have, and when you need more. This real-time visibility is a game-changer, especially for marine businesses dealing with a diverse range of parts and supplies.

Key components often include:

- Inventory management software: The brain of the operation, tracking stock levels, sales, and orders across all channels.

- Barcode scanners: For quick and accurate recording of items as they move in and out.

- RFID tags: Advanced tracking that allows for scanning multiple items simultaneously without direct line-of-sight.

The core difference from manual methods lies in its proactive nature. Instead of finding a shortage when an item is needed (reactive), an automated system alerts you when stock levels hit a predetermined reorder point (proactive). This allows you to restock before you run out, ensuring continuous availability. As QuickBooks explains, it’s a system that helps businesses keep track of their stock levels automatically with minimal human intervention. You can read more about it in their guide: Automated inventory management: Definition, benefits, and examples .

How Automation Solves Manual Inaccuracies

The most glaring flaw of manual inventory is its susceptibility to human error. A misplaced decimal, a forgotten entry, or a miscounted item can throw off your entire stock count, leading to a cascade of problems. Automated inventory control virtually eliminates these pitfalls.

By integrating barcode or RFID scanning, every item’s movement is recorded accurately and instantly. This data then synchronizes across all your sales channels and locations in real time. If a part is used for a repair job, the system updates immediately, reflecting the change across your entire inventory. This means:

- Reduced human error: With automated data capture, the chance of manual entry mistakes plummets.

- Real-time data synchronization: Whether you have items in your main warehouse, a service van, or a remote storage unit, the system provides a unified, up-to-the-minute view of your stock.

- Increased accuracy: This precision directly translates to more reliable stock levels, fewer discrepancies, and a clearer understanding of your assets.

- Improved data-driven decisions: With accurate, real-time data at your fingertips, you can make informed decisions about purchasing, pricing, and resource allocation. A recent McKinsey survey showed that an automated supply chain increased revenue by up to 4%, reduced excess inventory by up to 20%, and decreased supply chain costs by up to 10%. These are significant improvements that stem directly from better data.

Core Benefits of an Automated System

Implementing an automated system isn’t just about fixing problems; it’s about open uping new levels of performance and potential for your marine business. The advantages extend far beyond mere stock counting.

Here’s how automated inventory control becomes a cornerstone of your success:

- Efficiency: Streamlined workflows mean less time spent on mundane tasks and more time focused on core business activities.

- Cost reduction: By optimizing stock levels and minimizing errors, you save money on storage, waste, and lost sales.

- Scalability: As your business grows, your inventory system can grow with you without becoming a bottleneck.

- Customer satisfaction: Consistent product availability and accurate fulfillment lead to happier, more loyal customers.

How Automation Improves Efficiency and Reduces Costs

Efficiency and cost reduction are two sides of the same coin when it comes to automated inventory control. The elimination of manual tasks and the precision of real-time data directly impact your bottom line.

- Optimized stock levels: Automated systems help you find that “sweet spot” between having too much and too little. You can set reorder points and rely on the system to notify you—or even automatically reorder—when stock dips. This prevents costly overstocking that ties up capital and space, and equally costly stockouts that lead to lost sales. According to McKinsey, automation can lead to significant cost savings by minimizing errors and optimizing inventory levels.

- Reduced labor costs: Imagine freeing up your team from endless manual counts and data entry. With automated systems, tasks like stock-taking become faster and less frequent. This reduces the need for extensive manual labor and allows your skilled staff to focus on high-value work, like servicing vessels or engaging with customers. Considering that warehouses remain understaffed by 10–25%, automation can help bridge this labor gap.

- Preventing stockouts and overstocking: This is arguably one of the biggest cost-saving benefits. Stockouts mean missed sales opportunities, while overstocking leads to increased storage costs, potential spoilage or obsolescence, and reduced cash flow. Automated systems predict demand more accurately and trigger timely reorders, ensuring you always have what you need, when you need it.

- Streamlined workflows: From the moment a part is ordered to its installation in a vessel, automated inventory control orchestrates a smooth, efficient flow. This optimization extends to your entire service operation, as we discuss in our guide From First Call to Final Invoice: Streamlining the Yacht Service Workflow.

Enhancing Customer Satisfaction and Business Scalability

Happy customers and the ability to grow your business are two powerful outcomes of effective automated inventory control.

- Ensuring product availability: Nothing frustrates a customer more than ordering a product only to find it’s out of stock. Automated inventory control helps you avoid stockouts by providing real-time visibility and prompting timely reorders. This ensures that when a customer needs a part or service, you can deliver. For marine businesses, this means less downtime for vessels and happier boat owners.

- Accurate order fulfillment: When your inventory data is precise, you can fulfill orders accurately and efficiently. This builds trust and improves your reputation for reliability.

- Meeting ecommerce demand: The world of commerce is increasingly digital. US ecommerce sales are forecasted to grow by 9.3% in 2023 to reach $1.137 trillion. This growth puts immense pressure on inventory systems. Automated systems can seamlessly integrate with online sales channels, updating stock levels in real time and preventing overselling. This capability is crucial for businesses looking to expand their reach and manage increased demand without compromising service quality.

- Simplified scalability: As your marine business grows, so does the complexity of your inventory. Manual systems quickly become overwhelmed. Automated inventory control is designed to scale. It can handle more SKUs, more locations, and higher transaction volumes without a proportional increase in administrative burden. This allows your business to expand confidently, knowing your inventory system can keep pace. We dig deeper into how this impacts growth in our article, How Yacht Logic Pro Helps Boatyards Scale Without Sacrificing Quality.

Key Features and Types of Automated Inventory Systems

When we talk about automated inventory control, we’re discussing a spectrum of technological solutions. Choosing the right technology means understanding the various system components and software features available, and how they align with your specific business needs.

Essential Features of an Automated Inventory Control System

A robust automated inventory control system should come equipped with a suite of features designed to maximize efficiency, accuracy, and insight. Here are the must-haves:

- Barcode/RFID scanning: This is the backbone of automated data capture. Barcode scanners quickly record items as they move, while RFID (Radio Frequency Identification) tags allow for even faster, non-line-of-sight scanning, ideal for high-volume environments or tracking high-value marine equipment.

- Real-time multi-location tracking: For marine businesses often operating across multiple marinas, warehouses, or even service vehicles, the ability to track inventory across all locations in real time is non-negotiable. This ensures you know exactly where every part is at any given moment.

- Automated reorder points: Set minimum stock levels, and the system will automatically notify you when inventory dips, or even generate purchase orders automatically. This ensures you can set reorder points with inventory control software and avoid stockouts before they happen.

- Demand forecasting: Leveraging historical sales data and, ideally, AI-powered algorithms, the system predicts future demand. This helps you make smarter purchasing decisions, optimize stock levels, and prepare for seasonal fluctuations in the marine industry.

- Reporting and analytics: Powerful reporting tools provide insights into inventory turnover, slow-moving items, carrying costs, and profitability. This data is crucial for continuous improvement and strategic planning.

- Integrations (Accounting, POS, CRM): A truly effective system doesn’t operate in a silo. It should seamlessly integrate with your existing business software, such as accounting platforms (like QuickBooks), Point of Sale (POS) systems, and Customer Relationship Management (CRM) tools. This creates a unified data ecosystem, eliminating double data entry and providing a holistic view of your operations.

For a deeper dive into what makes a great software solution for marine businesses, check out our comprehensive guide: What to Look For in Yacht Service Management Software: A Buyer’s Checklist.

Fully Automated vs. Semi-Automated Systems

When we discuss automated inventory control, it’s important to understand that there are different levels of automation. We can broadly categorize systems into manual, semi-automated, and fully automated approaches.

| System Type | Cost | Accuracy | Implementation | Best For |

|---|---|---|---|---|

| Manual | Low | Low | Simple | Micro-businesses with very low inventory volume |

| Semi-Automated | Moderate | Good | Moderate | Growing SMEs, businesses using barcode scanning & POS |

| Fully Automated | High | Very High | Complex | Large enterprises, complex supply chains, high-value items |

Manual Systems (Periodic Inventory): This is the traditional approach, relying on physical counts at set intervals (e.g., end of month, end of year) to update stock records. While simple and low-cost to implement, it’s highly prone to error and provides no real-time visibility. It’s best suited for businesses with very low inventory volumes or unique, high-value items where individual tracking is feasible.

Semi-Automated Systems (Perpetual Inventory with some manual input): These systems combine technology with some manual processes. They typically use software for continuous, real-time tracking (perpetual inventory) of stock levels, often integrated with barcode scanners and POS systems. While the software automates much of the data entry and tracking, some manual intervention might still be needed for tasks like receiving or cycle counting. This approach offers a good balance of cost and efficiency for many growing small to medium-sized businesses.

Fully Automated Systems (Perpetual Inventory with advanced tech): These represent the pinnacle of automated inventory control, leveraging advanced technologies like RFID, IoT (Internet of Things) devices, and robotics. In a fully automated setup, items are tracked seamlessly as they move, often without direct human scanning. For example, smart shelves equipped with IoT sensors can detect when stock levels are low and automatically trigger reorders. These systems offer the highest accuracy and efficiency but come with a higher initial investment and more complex implementation. They are ideal for large enterprises, businesses with high-value or high-volume inventory, and complex supply chains.

You can explore more about these distinctions in the Types of Inventory Control Systems resource.

Implementation and the Future of Automated Inventory Control

Moving to automated inventory control is a significant step that positions your marine business for long-term success. It requires strategic planning and a forward-thinking mindset to future-proof your operations.

Choosing the Right Automated Inventory Control System for Your Business

Selecting the ideal system for your marine business isn’t a one-size-fits-all decision. It’s a strategic investment that requires careful consideration of your unique operations.

- Needs Assessment: Start by thoroughly evaluating your current processes. What are your biggest pain points with manual inventory? Are you frequently experiencing stockouts of critical parts? Is too much capital tied up in excess inventory? What are your growth aspirations? Clearly defining your goals—whether it’s reducing costs, improving efficiency, or enhancing customer satisfaction—will guide your choice.

- Scalability Planning: Your business is dynamic. The system you choose today should be able to grow with you tomorrow. Consider if it can handle increased inventory volume, additional locations, and new product lines without requiring a complete overhaul.

- Budget Considerations: Weigh the initial costs of software, hardware, and implementation against the long-term ROI from cost savings, increased efficiency, and improved customer satisfaction.

- Team Training: Even the most advanced system is only as good as the people using it. Factor in comprehensive training for your team to ensure smooth adoption and maximum utilization of the new system’s capabilities.

- Best Practices for Implementation:

- Regular Cycle Counts: While automation reduces the need for full physical counts, periodic reviews are still essential. Conduct a physical inventory count at least once a year to reconcile discrepancies and ensure system accuracy.

- Data Hygiene: Standardize your naming conventions, product classifications, and location tags from day one. Clean data is crucial for the system to function effectively.

- Integration: Ensure the system integrates seamlessly with your existing operational software (e.g., scheduling, CRM, accounting). This creates a unified platform and avoids data silos.

For marine businesses, generic solutions often fall short. We believe in Tech That Works at Sea: Why Marine-Specific Software Beats Generic Tools Every Time.

The Future: AI, IoT, and Data-Driven Forecasting

The landscape of automated inventory control is constantly evolving, with exciting advancements on the horizon that promise even greater efficiency and insight.

- AI-powered predictive analytics: Artificial intelligence is revolutionizing forecasting. AI algorithms can analyze vast amounts of historical sales data, seasonal trends, market fluctuations, and even external factors to predict demand with unprecedented accuracy. This helps businesses optimize stock levels, prevent stockouts, and reduce waste. AI can even suggest rebalancing stock between sites or adjusting thresholds before issues arise. The McKinsey survey noted that AI-powered automation can increase revenue by up to 4%.

- IoT sensors: The Internet of Things is bringing new levels of real-time visibility. Imagine smart shelves that automatically detect when stock levels are low and trigger reorder alerts, or sensors that monitor the environmental conditions of sensitive marine parts.

- Blockchain for traceability: This technology offers a secure, transparent, and immutable record of an item’s journey from manufacturer to end-user. For high-value marine components, blockchain can improve authenticity verification, track warranties, and streamline recalls, building immense trust and transparency in the supply chain.

- Sustainability: Future systems will increasingly focus on minimizing environmental impact. This includes optimizing inventory to reduce waste (e.g., preventing perishables from expiring), optimizing delivery routes, and promoting eco-friendly packaging.

- Robotics and automated machinery: In larger warehouses, automated guided vehicles (AGVs) and robotic arms are already assisting with sorting, picking, and packing, further reducing manual labor and increasing speed.

- 5G connectivity: The rollout of 5G will enable faster data transfer and more robust connectivity for IoT devices and mobile inventory solutions, enhancing real-time communication and operational efficiency in warehouses and beyond.

These emerging trends highlight a future where inventory management is not just automated but intelligent, predictive, and seamlessly integrated into every aspect of your business. This truly data-driven approach is the future of marine industry service, as we discuss in Why Data-Driven Yacht Service is the Future of the Marine Industry.

Frequently Asked Questions about Automated Inventory

We understand you might have more questions about making the leap to automated inventory management. Here are some common queries we hear:

What are the main types of inventory management systems?

The four primary types of inventory management systems, in ascending order of complexity and automation, are:

- Periodic Inventory Management: This is a manual system where physical counts are conducted at specific, predetermined intervals (e.g., monthly, quarterly, annually) to update stock records. It’s simple but lacks real-time accuracy.

- Perpetual Inventory Management: This system continuously tracks inventory levels in real time as items are bought, sold, or moved. It relies on technology like software, POS systems, and barcode scanners for constant updates.

- Barcode Inventory Systems: These systems use scannable barcodes on items to quickly and accurately record inventory movements. They significantly reduce manual data entry and improve tracking speed.

- Radio Frequency Identification (RFID) Systems: An advanced form of tracking, RFID uses radio waves to read information from tags attached to items. This allows for rapid, non-line-of-sight scanning of multiple items simultaneously, offering superior accuracy and efficiency.

How does automation improve inventory forecasting?

Automated inventory control dramatically improves forecasting capabilities by:

- Leveraging real-time sales data: Instead of relying on outdated sales figures, automated systems provide immediate insights into what’s selling, allowing for quicker adjustments to demand predictions.

- Analyzing historical trend data: The software can process vast amounts of past sales data to identify patterns, seasonality, and long-term trends that human analysis might miss.

- Utilizing AI algorithms: Advanced systems employ artificial intelligence and machine learning to build sophisticated predictive models. These algorithms can factor in a multitude of variables (e.g., weather, economic indicators, marketing campaigns) to generate highly accurate forecasts.

- Reducing guesswork: By providing data-driven insights, automation minimizes reliance on intuition or “gut feelings,” leading to more precise inventory planning and reduced risks of overstocking or stockouts.

What is the first step to implementing an automated inventory system?

The first and most crucial step to implementing an automated inventory control system is conducting a thorough needs analysis and defining clear goals. This involves:

- Identifying pain points: Pinpoint the specific challenges and inefficiencies in your current manual inventory process. Are stockouts common? Is too much labor spent on counting? Are you struggling with accurate financial reporting related to inventory?

- Defining clear goals: What do you hope to achieve with automation? Examples include reducing carrying costs by X%, eliminating stockouts, improving order fulfillment speed, or gaining real-time visibility across all locations. Specific, measurable goals will help you choose the right system and track its success.

- Assessing current processes and technology: Understand your existing workflows and any software or hardware you currently use. This helps determine what can be integrated and what needs to be replaced, ensuring a smooth transition and compatibility.

By clearly understanding your needs and objectives, you can then move on to researching and selecting a system that truly aligns with your business requirements and budget.

Conclusion

The journey from manual, error-prone inventory management to a streamlined, intelligent, and proactive system is not just an upgrade—it’s a change. Automated inventory control is no longer a luxury but a necessity for marine businesses looking to thrive in a competitive and rapidly evolving landscape.

We’ve seen how automation addresses the high costs and inefficiencies of manual methods, driving significant improvements in:

- Accuracy: Eliminating human error and providing real-time data.

- Efficiency: Streamlining workflows and reducing labor costs.

- Cost Savings: Preventing stockouts, overstocking, and waste.

- Scalability: Enabling your business to grow without operational bottlenecks.

- Customer Satisfaction: Ensuring product availability and reliable service.

For marine businesses, where specialized parts, complex maintenance schedules, and customer trust are paramount, an all-in-one solution that integrates inventory with overall operations is a game-changer. Automation isn’t just about managing parts; it’s about optimizing your entire service delivery, ensuring your technicians are productive, your vessels are maintained, and your customers are delighted.

Ready to open up true efficiency in your marine operations? Explore Yacht Logic Pro today. We offer an all-in-one, AI-powered marine maintenance and operations software built specifically for service-driven marine businesses. Our system automates maintenance, manages technicians, tracks inventory, and syncs finances, unifying your operations and eliminating manual data entry to save you time and boost your profits.

Ready to unlock true efficiency in your marine operations? Explore Yacht Logic Pro today.