Why Understanding Boat Repair Estimates Matters Before You Pay

Boat repair estimates can feel like reading a foreign language—cryptic line items, fluctuating labor rates, and unexpected fees that seem to appear out of nowhere. For boat owners, especially those managing multiple vessels or running marine businesses, unclear estimates lead to budget overruns, disputes with repair shops, and delays that keep boats out of commission longer than necessary.

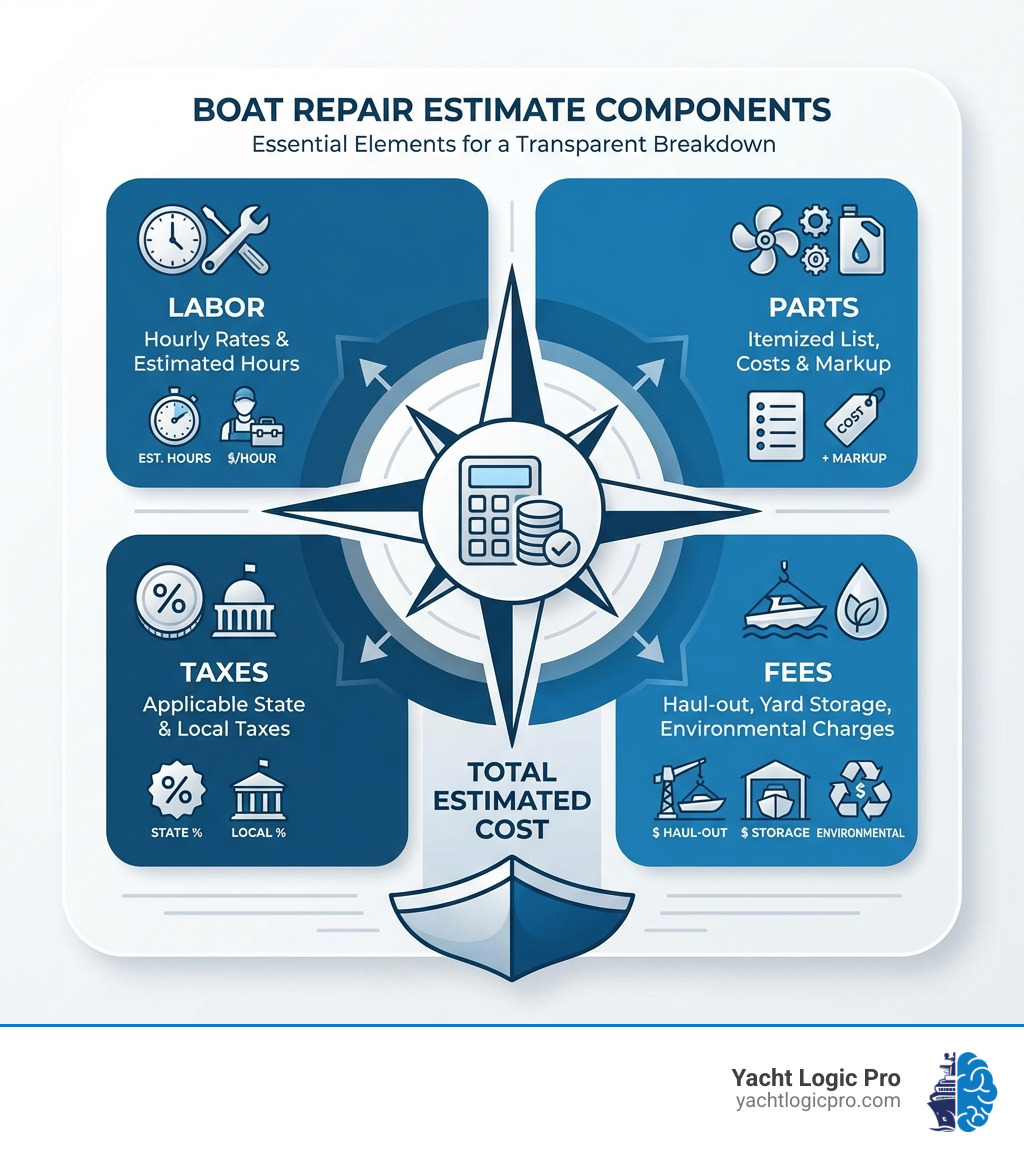

At a glance, a fair and accurate boat repair estimate should include:

- Labor costs – Hourly rates (typically $65-$130/hour depending on specialty) and estimated hours for the job

- Parts and materials – Itemized list with part numbers, quantities, and costs (including markup)

- Additional fees – Haul-out charges ($20-$40 per foot), yard storage, environmental fees, and shop supplies

- Clear terms – Whether it’s an estimate (approximation) or quote (fixed price), plus warranty and payment terms

The challenge isn’t just getting an estimate—it’s getting one that’s complete, transparent, and truly reflects what you’ll pay when the job is done. Without this clarity, you’re left vulnerable to surprise charges, scope creep, and the frustrating “while we’re in there” conversations that can double your final bill.

I’m Kevin Kates, founder of Yacht Logic Pro, and over the years I’ve helped countless yacht owners and marine businesses steer the complexities of repair costs and vendor relationships, including evaluating and negotiating boat repair estimates that protect their interests. Understanding what you’re paying for—and why—is the foundation of smart vessel management and avoiding costly misunderstandings with repair yards.

Decoding the Document: The Anatomy of a Boat Repair Estimate

When you receive a boat repair estimate, it’s more than just a number; it’s a detailed breakdown of the projected costs for getting your vessel back in prime condition. Understanding each component is crucial for evaluating its fairness and accuracy. We’ll typically see sections for labor, parts and materials, and various fees, all contributing to the final tally.

Labor Costs: The Price of Expertise

Labor costs are often the most significant portion of any boat repair estimate, reflecting the specialized skills and time marine technicians dedicate to your vessel. These costs are usually calculated in one of two ways:

- Hourly Rates: This is the most common method. Our research shows that labor rates for engine work can range from $95 to $130 per hour, plus materials. General service rates for plumbing, HVAC, and other general boat work typically fall between $65 and $115 per hour. For electrical and electronics troubleshooting and repair, you can expect to pay $85 to $125 per hour. These rates vary based on the technician’s expertise, the complexity of the job, and the shop’s location and overhead. A good estimate will clearly list the hourly rate and the estimated number of hours for each task.

- Flat-Rate Billing: For common, routine services (like an oil change or winterization), some shops might offer a flat rate. This can provide predictability, but understand exactly what’s included in that flat rate.

Specialized labor, such as certified engine mechanics or ABYC (American Boat & Yacht Council) certified technicians for electrical systems, often command higher rates due to their advanced training and specific expertise. We always recommend inquiring about the certifications and experience of the technicians working on your boat, especially for critical systems.

Parts and Materials: What’s Being Installed?

This section of your boat repair estimate should be carefully detailed. It lists every component and consumable required for the repair. A comprehensive parts list will include:

- Itemized Parts List: Each part, from a small O-ring to a new engine component, should be listed individually.

- Part Numbers: Including manufacturer part numbers allows you to cross-reference and verify pricing or specifications if needed.

- Quantities: The number of units for each part.

- Cost Per Item: The price the shop is charging for each part.

- Parts Markup: Shops typically apply a markup to the cost of parts to cover their overhead, shipping, and administrative costs. While not always explicitly stated as a percentage, it’s a standard business practice. For example, if you supply your own electronics, shops might charge a higher labor rate to compensate for their lost markup on those parts.

- OEM vs. Aftermarket Parts: Original Equipment Manufacturer (OEM) parts are made by the boat or engine manufacturer, while aftermarket parts are produced by other companies. OEM parts often cost more but ensure exact fit and performance.

- Miscellaneous Materials: This category covers consumables like shop towels, cleaning solvents, fasteners, sealants, and other small items not tied to a specific part number but necessary for the repair.

Beyond the Basics: Haul-Out, Yard Fees, and Other Charges

Repairing a boat often involves more than just labor and parts. Several other fees can significantly impact the total cost, especially if the work needs to be done out of the water:

- Haul-Out Cost: If your boat needs to be removed from the water for repairs, this fee covers the use of travel lifts or cranes. For a haul, prep, bottom paint, and launch job, our research indicates you can expect to pay $20 to $40 per foot. This cost can vary based on boat size and location.

- Pressure Washing: Often included with a haul-out, this cleans the hull before work begins.

- Blocking Fees: Charges for placing your boat on blocks or stands in the yard.

- Daily Yard Storage: If repairs take several days or weeks, you’ll likely incur daily storage fees for the time your boat occupies space in the yard.

- Environmental Fees: These cover the proper disposal of hazardous waste (e.g., old oil, paint, solvents) generated during the repair process.

- Shop Supply Charges: A general fee to cover common workshop supplies not individually itemized.

- Subcontracted Services: If the primary repair shop needs to bring in specialists (e.g., for canvas work, specialized electronics, or engine rebuilds at a machine shop), these costs will be listed.

Estimate vs. Quote: Knowing the Difference

It’s crucial to understand the distinction between a boat repair estimate and a quote:

- Estimate: An estimate is an approximation of the cost of repairs. It’s based on the shop’s best judgment of the work required and the potential issues. It is not a final price and can change as work progresses, especially if unexpected problems are finded.

- Quote: A quote, or a firm quote, is a fixed price for the specified work. Once a quote is provided and accepted, the shop is generally bound by that price, barring any unforeseen circumstances explicitly outlined in the agreement. For significant repairs or “big rehab jobs,” we almost always recommend asking for and going with a firm quote for both labor and materials, in writing, before any work begins. This provides much greater financial certainty.

While an estimate gives you a ballpark figure, a quote offers commitment. For larger projects, always push for a detailed, fixed quote to protect your budget.

Key Factors That Influence Your Boat Repair Estimates

Several variables can significantly sway the final cost of your boat repair estimates. Understanding these factors empowers us to anticipate expenses and make informed decisions.

The Impact of Your Boat’s Age, Condition, and Type

The older your boat, the more likely it is to require repairs, and often more extensive ones. Deferred maintenance on an older vessel can lead to compounding issues, making repairs more costly. For instance, a 30-foot classic FRP boat restoration project we saw involved $25,000 for engine rebuilds and hired tradesmen, plus $10,000 in owner’s labor, for a total investment of $60,000. This highlights that older boats often demand substantial investment to return to good condition.

The overall condition of your boat is paramount. A boat that has been well-maintained will typically have lower repair costs than one that has been neglected. Structural integrity is a key concern, as issues like hidden rot or delamination can drastically increase repair complexity and cost.

Your boat type also plays a significant role in boat repair estimates:

- Sailboats: These vessels require specialized care, particularly focusing on sail and rigging maintenance. Their upkeep costs about $1,500 to $4,000 a year, which includes sail inspection and repair ($500-$1,000) and rigging inspection and maintenance ($200-$500).

- Powerboats/Yachts: Larger, more complex vessels like cabin cruisers and yachts can incur substantial annual upkeep, ranging from $5,000 to $20,000 or more annually. A Motoryacht Findy 40, serviced once per year, costs about €10,000 annually for maintenance.

The materials used in your boat’s construction (fiberglass, wood, aluminum) also affect repair costs. Wooden boats, for example, often require more labor-intensive maintenance.

Saltwater vs. Freshwater: The Corrosion Factor

This is a big one! The environment your boat operates in dramatically affects its maintenance and repair needs.

- Corrosive Effects of Salt: Saltwater is highly corrosive. It accelerates the degradation of metal parts, protective coatings, and can lead to increased wear on engines, propellers, and other critical components. Our research confirms that saltwater use significantly increases maintenance costs because it wears down engines, propellers, and metal parts faster, leading to more frequent cleaning, upkeep, and replacements.

- Increased Wear: Components like sacrificial anodes (zincs) need more frequent replacement in saltwater to protect other metals from galvanic corrosion. Electrical systems are also more vulnerable to corrosion, leading to shorts or malfunctions. Through-hull fittings, seacocks, and plumbing systems are constantly exposed to saltwater and require diligent inspection and maintenance to prevent leaks and failures.

- Higher Maintenance Costs: Boaters in saltwater environments should anticipate higher annual maintenance and repair budgets compared to those in freshwater.

Estimating Specialized Repairs: From Fiberglass to Engine Rebuilds

Some repairs are inherently more complex and costly due to the specialized skills, tools, and materials involved.

- Fiberglass and Gelcoat Repair: These repairs are highly labor-intensive, requiring extensive prep work, careful application, and meticulous finishing to match the original hull. Expect to pay anywhere between $150 to $250 per foot (and up) to have a hull painted with two-part paint.

- Engine Rebuilds and Transmission Work: These are major undertakings. An engine rebuild typically costs about 50% to 60% of the price of a brand-new engine. While still substantial, it can be a cost-effective alternative to full replacement. Labor rates for engine work vary widely, but figure on somewhere between $95 and $130 an hour, plus materials.

- Electronics Installation and Repair: Modern marine electronics are sophisticated. Troubleshooting and repair jobs for electrical/electronics generally run between $85 and $125 per hour. Installation of new navigation suites or complete rewiring can be very complex.

- Painting: Beyond hull painting, bottom painting is a regular expense. For a haul, prep, bottom paint, and launch job, expect to pay $20 to $40 per foot. For a 32 ft fiberglass boat, antifouling application usually costs between €750 and €1,000.

As you can see, the type and extent of the repair significantly influence the final boat repair estimates. For a deeper dive into these costs, check out Used Boats: What’s It Going to Cost to Fix This Thing?.

How to Get a Fair and Accurate Boat Repair Estimate

Securing a fair and accurate boat repair estimate is not just about finding the lowest price; it’s about transparency, understanding the scope of work, and ensuring quality so your boat spends more time on the water and less time in the yard. Here’s how we approach it.

The Power of Clear Communication

Effective communication is the cornerstone of a successful repair experience. When you approach a repair shop, provide them with as much information as possible:

- Detailed Problem Description: Clearly articulate the issue. What are the symptoms? When did they start? Under what conditions do they occur?

- Photos and Videos: Visual documentation can be incredibly helpful, especially for intermittent problems or visible damage.

- Maintenance History: Provide records of past services, repairs, and any relevant upgrades. This helps technicians understand the boat’s history and potential underlying issues.

- Desired Outcome: What are your expectations for the repair? Do you want a quick fix, a long-term solution, or a staged plan that fits a specific budget and timeline?

- Asking Questions: Ask for clarification on anything you don’t understand in the estimate. A reputable shop will be happy to explain line items, time estimates, and alternative options.

Yard managers who use platforms like Yacht Logic Pro can capture all of this information in a structured digital work order, attach your photos and videos, and make sure nothing is lost between the first phone call and the final invoice.

Why You Should Always Get Multiple Estimates

For any significant repair, we strongly advise getting at least two, and ideally three, boat repair estimates. This practice offers several advantages:

- Comparing Prices: It allows you to gauge the market rate for the specific repair, helping you identify potential overcharges or suspiciously low bids.

- Evaluating Scope of Work: Different shops might propose different solutions or levels of service. Comparing estimates helps you understand the various approaches and choose the one that best fits your needs and budget.

- Assessing Shop Professionalism: The way a shop prepares and presents an estimate can tell you a lot about their professionalism and attention to detail.

- Negotiation Leverage: Having multiple estimates can give you leverage to negotiate pricing or terms.

- Avoiding Overcharges: This due diligence helps protect you from inflated costs. Our research suggests that for “big jobs,” you should always get two or more quotes.

On the business side, standardized, software-generated estimates make it easier for marine service yards to price consistently, justify their numbers, and stand behind them when customers compare offers.

Reading the Fine Print: What to Look for in Your Estimate

Once you have your boat repair estimates in hand, don’t just glance at the total. Dive into the details. Here’s a checklist of what to scrutinize:

- Detailed Scope of Work: Does it clearly describe what will be repaired or replaced? Avoid vague language.

- Itemized Parts and Labor: Ensure all parts are listed with quantities and individual prices. Labor hours for each task should also be specified, along with the hourly rate.

- Warranty Information: What kind of warranty, if any, does the shop offer on parts and labor? How long does it last and what does it exclude?

- Payment Terms: What are the deposit requirements? When is final payment due? Are there late payment penalties or storage charges if you cannot pick up the boat immediately?

- Timeline: Does the estimate provide a realistic timeframe for completion, including any dependencies like parts availability?

- Change Order Process: Critically important. How will the shop handle unexpected findings or changes to the repair plan? This should be clearly defined to avoid surprises later.

Modern service software can help ensure these details are captured the same way every time, with standard terms and digital sign-off so both the yard and the owner know exactly what has been approved.

Navigating the Repair Process: Common Pitfalls and Surprises

Even with the most carefully prepared boat repair estimate, the repair process can sometimes throw us a curveball. Being prepared for unexpected findings and knowing how to avoid common pitfalls can save significant headaches and expenses.

“While We’re in There…”: Handling Unexpected Findings

It’s a phrase every boat owner dreads: “While we’re in there, we found something else.” Boats, especially older ones, can hide a multitude of sins. During a repair, technicians might uncover:

- Hidden Rot or Corrosion: What started as a small leak might reveal extensive wood rot or metal corrosion behind panels.

- Delamination: In fiberglass boats, water intrusion can lead to delamination, weakening the hull or deck structure.

- Failing Systems: A routine engine service might expose a failing transmission or a compromised electrical component.

Our research emphasizes the importance of addressing these unforeseen issues. The field survey/repair specifications document we reviewed explicitly states that the repairer must bring “any concealed damages finded during repairs to the attention of the surveyor” and obtain the “surveyor’s opinion on repair methods for additional damages.”

This is where a clear change order process becomes your best friend. A reputable shop will:

- Stop work on the newly finded issue.

- Contact you immediately to explain the finding, its implications, and recommended solutions.

- Provide a written change order detailing the additional work, parts, labor, and new cost implications.

- Require your written authorization before proceeding with any additional work.

Never authorize additional work verbally. Always get it in writing, including updated cost and timeline projections, to maintain control over your budget and schedule.

Common Pitfalls to Avoid When Reviewing an Estimate

Reviewing boat repair estimates requires a discerning eye. Here are some common traps we strive to help our clients avoid:

- Vague Descriptions: An estimate that simply says “Engine Repair” without detailing what specific components will be addressed or replaced is a red flag. Insist on specifics.

- Lumped Costs: Watch out for broad categories like “Miscellaneous Materials” or “Shop Supplies” that seem disproportionately high or lack explanation. While some general costs are expected, excessive lumped costs can hide inflated charges.

- Unusually Low Prices: While a good deal is always welcome, an estimate significantly lower than others for the same scope of work should raise suspicion. As one of our sources cautions, “The lowest priced contractor will not do a good job.” It could indicate corner-cutting, hidden fees, or a lack of understanding of the true scope.

- High-Pressure Tactics: If a shop rushes you to approve an estimate or discourages you from getting other opinions, it’s a sign to proceed with caution.

- Lack of Warranty: Always ensure the estimate specifies a warranty on both parts and labor. Without it, you’re unprotected if the repair fails shortly after completion.

- Underestimating Time: Our research into boat restoration projects points out that “Every job takes 4 times longer than you thought it would” and “Little jobs are never easy.” While an estimate isn’t a firm timeline, be wary of overly optimistic projections for complex work.

For deeper insights into the realities of major boat projects and the importance of realistic estimation, consider reading Fundamentals of Restoration Projects.

The Future of Fair Estimates: How Technology is Changing the Game

The marine industry, traditionally hands-on, is increasingly embracing technology to improve efficiency, accuracy, and transparency. This shift is profoundly impacting how boat repair estimates are created, managed, and communicated. At Yacht Logic Pro, we believe that Data-Driven Yacht Service is the Future of the Marine Industry.

How Software Creates Better Estimates

Modern marine repair software, like our Yacht Logic Pro platform, is revolutionizing the estimation process:

- Standardized Job Templates: Instead of starting from scratch, technicians can pull up pre-defined job templates for common services. This ensures consistency, reduces errors, and speeds up estimate creation.

- Integrated Parts Catalogs: Software can connect directly to parts suppliers (like Nexpart, PartsTech, and Epicor mentioned in our research). This provides real-time pricing and availability, ensuring that the parts costs in your estimate are current and accurate.

- Accurate Labor Guides: Sophisticated software often incorporates labor guides that suggest realistic timeframes for specific tasks, leading to more precise labor hour estimates.

- Digital Photo Documentation: Technicians can attach photos and videos directly to the estimate, visually documenting the damage and the proposed repair. This provides undeniable clarity for the boat owner.

- Customer Portals: Many systems offer customer portals where owners can view their estimates, track repair progress, and access historical service records, all from their computer or mobile device.

This technology automates maintenance, manages technicians, tracks inventory, and syncs finances for service-driven marine businesses, saving time and boosting profits by unifying operations and eliminating manual data entry.

Streamlining Approval and Communication

Beyond creation, technology significantly streamlines the entire estimate and repair workflow:

- Digital Authorization: Customers can review and digitally sign estimates from anywhere, often directly from their smartphone. This eliminates delays associated with paper forms and faxes, allowing work to begin sooner.

- Text and Email Updates: Repair shops can send automated updates on repair status, notifications of unexpected findings, or requests for authorization via text or email, keeping customers informed in real-time.

- Centralized Records: All communication, estimates, change orders, and repair history are stored in one centralized digital location, making it easy for both the shop and the owner to access important information. This is a key component of the streamlined process we cover in From First Call to Final Invoice: Streamlining the Yacht Service Workflow.

This adoption of marine repair software means faster, more accurate, and more transparent boat repair estimates, ultimately leading to better customer satisfaction and more efficient operations for marine businesses.

Frequently Asked Questions about Boat Repair Estimates

We often hear similar questions from boat owners trying to make sense of their repair costs. Here are some of the most common ones:

What is the ‘10% rule’ for boat maintenance?

The ‘10% rule’ is a common guideline suggesting you budget 10% of your boat’s purchase price for annual maintenance and repairs. For example, a $50,000 boat would need around $5,000 for upkeep annually. While it’s a general rule of thumb, it helps us anticipate costs and avoid financial surprises. Factors like the boat’s age, condition, and whether it’s used in saltwater or freshwater can cause this percentage to fluctuate, potentially from 5% to 15%. For more details, refer to What Is the Rule of Thumb for Boat Maintenance Costs?.

How much does it cost to rebuild a boat engine?

An engine rebuild typically costs 50% to 60% of the price of a brand-new engine. This can be a cost-effective alternative to a full replacement, especially for well-maintained blocks. The final price depends on the extent of the damage, the specific parts needed, and the labor involved. Labor rates for engine work can vary significantly, but generally fall between $95 and $130 per hour.

Can I supply my own parts for a repair?

Some shops might allow you to supply your own parts, but it often comes with caveats. While you might save money on the part itself, the shop typically won’t warranty the part’s quality or longevity since they didn’t source it. Furthermore, they may charge a higher labor rate to compensate for their lost markup on the part, effectively negating some of your savings. We recommend discussing this upfront with your chosen repair facility to understand their policy and any associated implications for your boat repair estimates.

Conclusion: Setting Sail with Confidence

Navigating boat repair estimates doesn’t have to be a bewildering experience. By understanding the essential components of an estimate, recognizing the factors that influence costs, and employing smart communication strategies, we can ensure fair prices and quality repairs. Clear, itemized estimates build trust and allow us to make informed decisions about our valuable assets.

Proactive maintenance, informed budgeting, and transparent communication with marine service providers are key to enjoying your time on the water without unexpected financial storms. At Yacht Logic Pro, we’re dedicated to empowering marine businesses and boat owners with the tools to streamline operations, improve transparency, and ultimately, achieve a smoother sailing experience.

Ready to take control of your boat’s maintenance and repair process? Explore how Yacht Logic Pro can help you achieve fair winds and fair prices for all your marine service needs. Visit YachtLogicPro.com to learn more.